The

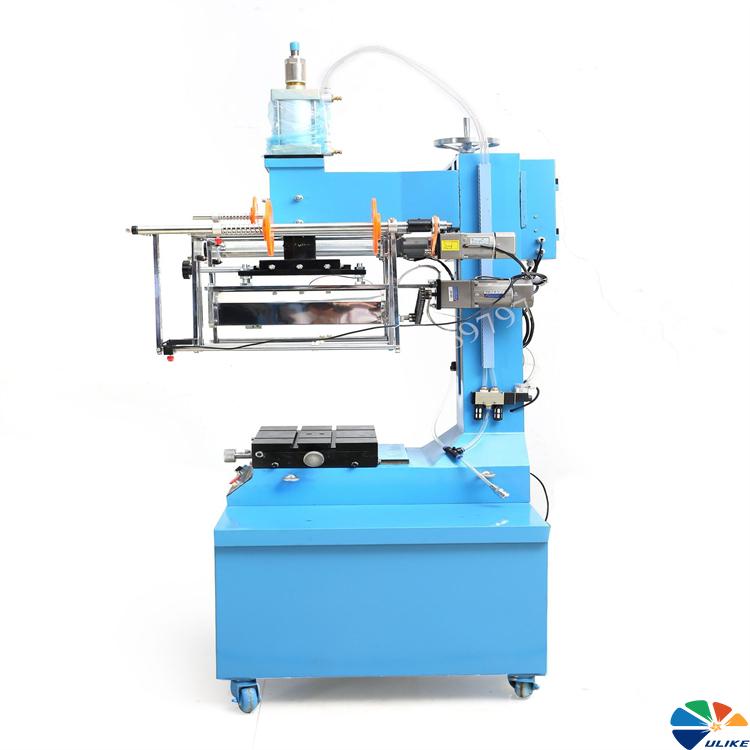

flat and round dual-purpose heat transfer machine is a multi-functional heat

transfer device designed for transferring patterns or text on flat and

cylindrical (or curved) objects. The device combines the functions of flat and curved

heat transfer machines, can handle objects of various shapes and materials, and

is widely used in multiple industries. The following is a brief introduction to

the flat and round dual-purpose heat transfer machine:

1.

Working principle

The flat and round dual-purpose heat transfer machine transfers the pre-printed

pattern from the transfer film or transfer paper to the surface of the

substrate by heating and pressurizing. Its core principle is the same as that

of traditional heat transfer machines, but with more flexible operation and

application range.

2.

Main features

Versatility:

The equipment can handle both flat and curved substrates and is suitable for a

variety of application scenarios.

Flexible

adjustment: Usually equipped with adjustable heating plates and clamps to

accommodate objects of different shapes and sizes.

Precise

control: It has a precise temperature and time control system to ensure

consistent results for each transfer.

Easy

operation: Equipped with a digital display and a simple operation interface, it

is easy for users to get started quickly.

3.

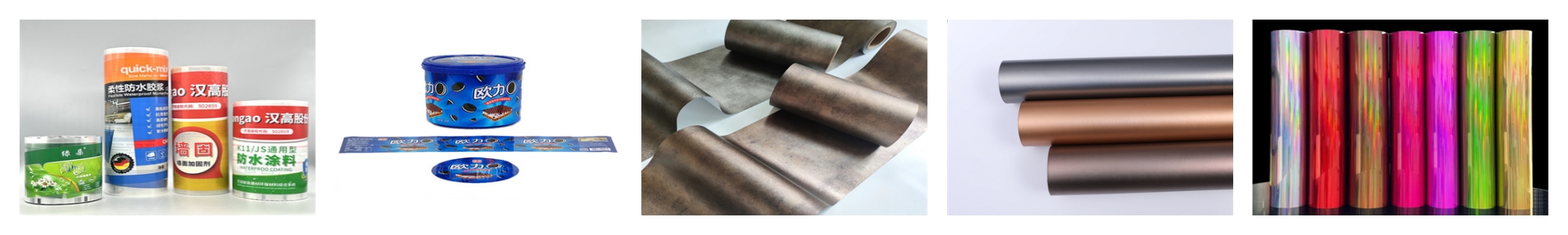

Scope of application

Advertisements

and logos: make billboards, logos, signs, etc.

Apparel

industry: print textiles such as T-shirts, hats, shoes, etc.

Gifts

and crafts: make personalized gifts, souvenirs, customized crafts, etc.

Home

decoration: print decorative materials such as tiles, wood boards, glass, etc.

Electronic

products: transfer mobile phone cases, notebook cases and other electronic

product accessories.

Bottles

and cups: print mineral water bottles, beverage bottles, thermos cups, etc.

4.

Advantages

High

efficiency: one device can handle a variety of shapes and materials, saving

space and cost.

High

quality: the transfer effect is bright, clear and durable, which can meet the

needs of high quality.

Flexibility:

suitable for small batch and multi-variety production, meeting the market needs

of personalization and customization.

Durability:

the equipment has a solid structure, long service life and low maintenance

cost.

5.

Precautions for use

Temperature

and time control: according to different substrates and transfer films, adjust

the appropriate temperature and time to ensure the best transfer effect.

Equipment

maintenance: clean the heating plate and fixture regularly to ensure the normal

operation and long life of the equipment.

Operational

safety: Pay attention to protection during operation to avoid burns and ensure

safe use.

6.

Equipment composition

Heating

device: used to heat the transfer film and substrate surface to ensure that the

pattern can be successfully transferred.

Fixed

device: used to fix substrates of different shapes to ensure that the substrate

will not move or deform during the transfer process.

Control

system: used to set and control parameters such as temperature, time and

pressure to ensure the accuracy of the transfer process.

Conversion

device: used to switch between flat and curved transfer modes to increase the

flexibility and scope of application of the equipment.

Summary

The

flat and round dual-purpose thermal transfer machine is an efficient and

versatile thermal transfer equipment that can meet the transfer needs of

objects of different shapes and materials. Its wide range of applications and

high-quality transfer effects have made it widely used in many industries such

as advertising, clothing, gifts, home decoration and electronic products.

Through precise temperature and time control, users can easily achieve a

variety of personalized and customized transfer tasks.

Heat Transfer

Machine Features:

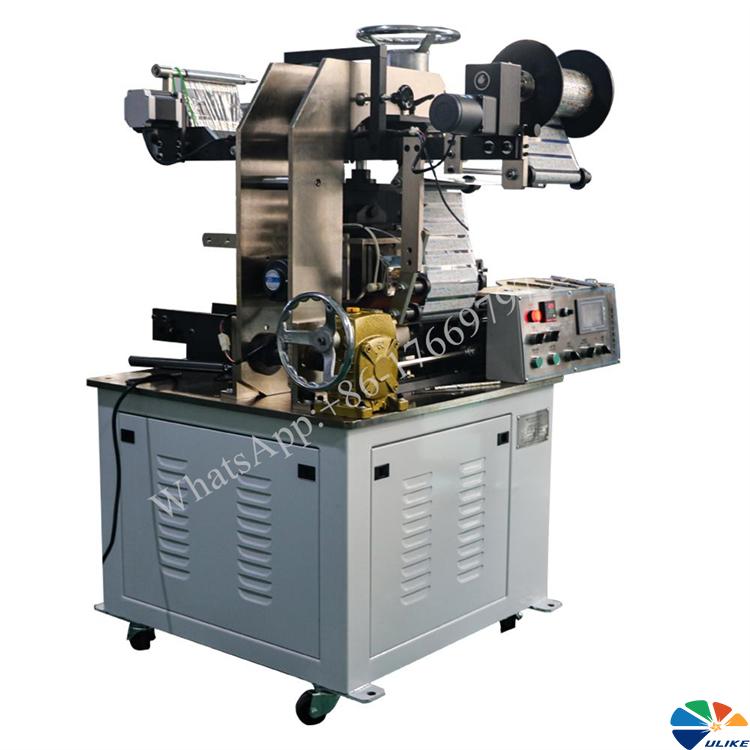

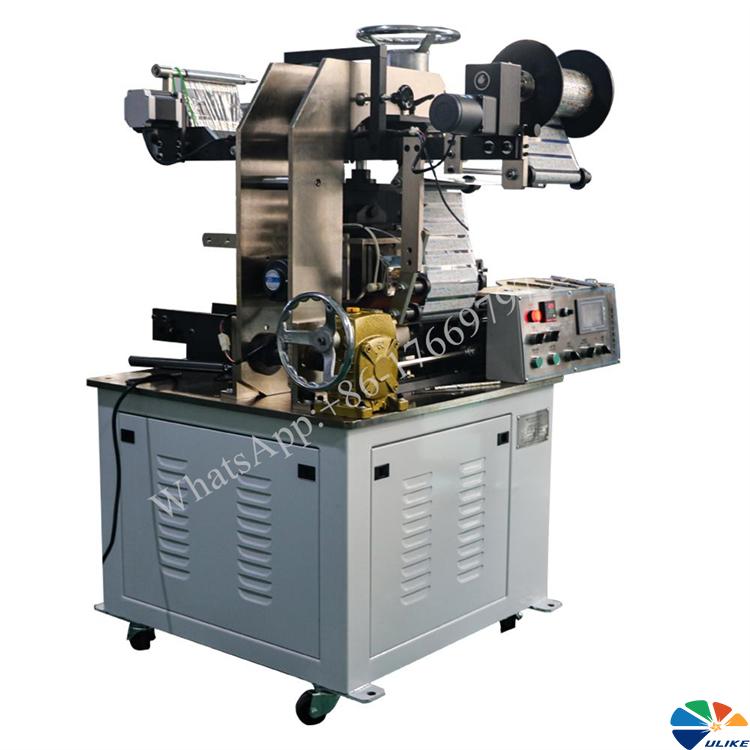

1.

Microprocessor control and LCD display (English version available) allow simple

operation; with built-in 5-digit counter

2. Rubber roller contacts with substrates in linear form to avoid pin holes on

stamping surface

3. High precision photo sensor is used to monitor and control the feeding of

foil with dots and a timer is used for the foil without dots.

4. Stamping head height is adjustable to meet the requirements for different

substrates with various heights

5. Worktable can be adjusted forward/backward and left/right, and turned

slightly

6. Profiling mechanism ensures proper stamping on irregular substrates

7. Capable of adjusting the stamping pressure, temperature and speed

8. Use pneumatic-hydraulic conversion cylinder to ensure smooth stamping

9. Auto foil feeding and collecting and the feeding length adjustable

10. Suitable for plane and round shape.

Parameters:

|

ITEM

|

UK-ZD1530Q-E

|

|

Max printing size

|

15cm x 30cm

|

|

Max printing speed

|

20 times / minute

|

|

Machine dimension

|

105cm x 85cm x 195cm

|

|

Machine weight

|

300KG

|

|

Air pressure

|

0.4 - 0.6 Mpa

|

|

Heating power

|

2 KW

|

|

Temperature range

|

0-300℃

|

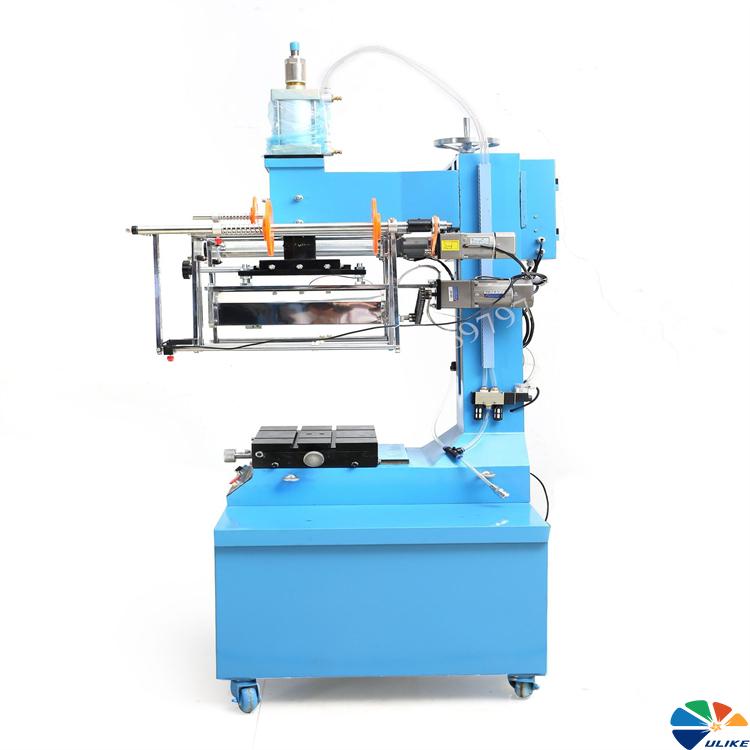

Specially

functions:

1.

This heat transfer machine is special for round/cylinder and

flat shape products printing.

2. The machine is with PLC system controller;

3. The table of all of our machines are made by mould, which make it has more

stable.

4.The

style machine is our general style.Its economic.But can print on many plastic

wood,or glass products printing.

![af]() Afrikaans

Afrikaans![sq]() Albanian

Albanian![am]() Amharic

Amharic![ar]() Arabic

Arabic![fr]() French

French![es]() Spanish

Spanish![ru]() Russian

Russian![de]() German

German![hy]() Armenian

Armenian![it]() Italian

Italian![ja]() Japanese

Japanese![ko]() Korean

Korean![pt]() Portuguese

Portuguese![hi]() Hindi

Hindi![az]() Azerbaijani

Azerbaijani![ro]() Romanian

Romanian![pl]() Polish

Polish![th]() Thai

Thai![el]() Greek

Greek![eu]() Basque

Basque![en]() English

English![zh-CN]() Chinese (Simplified)

Chinese (Simplified)![zh-TW]() Chinese (Traditional)

Chinese (Traditional)![be]() Belarusian

Belarusian![bn]() Bengali

Bengali![bs]() Bosnian

Bosnian![bg]() Bulgarian

Bulgarian![ca]() Catalan

Catalan![ceb]() Cebuano

Cebuano![ny]() Chichewa

Chichewa![co]() Corsican

Corsican![hr]() Croatian

Croatian![cs]() Czech

Czech![da]() Danish

Danish![nl]() Dutch

Dutch![eo]() Esperanto

Esperanto![et]() Estonian

Estonian![tl]() Filipino

Filipino![fi]() Finnish

Finnish![fy]() Frisian

Frisian![gl]() Galician

Galician![ka]() Georgian

Georgian![gu]() Gujarati

Gujarati![ht]() Haitian Creole

Haitian Creole![ha]() Hausa

Hausa![haw]() Hawaiian

Hawaiian![iw]() Hebrew

Hebrew![hmn]() Hmong

Hmong![hu]() Hungarian

Hungarian![is]() Icelandic

Icelandic![ig]() Igbo

Igbo![id]() Indonesian

Indonesian![ga]() Irish

Irish![jw]() Javanese

Javanese![kn]() Kannada

Kannada![kk]() Kazakh

Kazakh![km]() Khmer

Khmer![ku]() Kurdish (Kurmanji)

Kurdish (Kurmanji)![ky]() Kyrgyz

Kyrgyz![lo]() Lao

Lao![la]() Latin

Latin![lv]() Latvian

Latvian![lt]() Lithuanian

Lithuanian![lb]() Luxembourgish

Luxembourgish![mk]() Macedonian

Macedonian![mg]() Malagasy

Malagasy![ms]() Malay

Malay![ml]() Malayalam

Malayalam![mt]() Maltese

Maltese![mi]() Maori

Maori![mr]() Marathi

Marathi![mn]() Mongolian

Mongolian![my]() Myanmar (Burmese)

Myanmar (Burmese)![ne]() Nepali

Nepali![no]() Norwegian

Norwegian![ps]() Pashto

Pashto![fa]() Persian

Persian![pa]() Punjabi

Punjabi![sm]() Samoan

Samoan![gd]() Scottish Gaelic

Scottish Gaelic![sr]() Serbian

Serbian![st]() Sesotho

Sesotho![sn]() Shona

Shona![sd]() Sindhi

Sindhi![si]() Sinhala

Sinhala![sk]() Slovak

Slovak![sl]() Slovenian

Slovenian![so]() Somali

Somali![su]() Sudanese

Sudanese![sw]() Swahili

Swahili![sv]() Swedish

Swedish![tg]() Tajik

Tajik![ta]() Tamil

Tamil![te]() Telugu

Telugu![tr]() Turkish

Turkish![uk]() Ukrainian

Ukrainian![ur]() Urdu

Urdu![uz]() Uzbek

Uzbek![vi]() Vietnamese

Vietnamese![cy]() Welsh

Welsh![xh]() Xhosa

Xhosa![yi]() Yiddish

Yiddish![yo]() Yoruba

Yoruba![zu]() Zulu

Zulu