Introduction

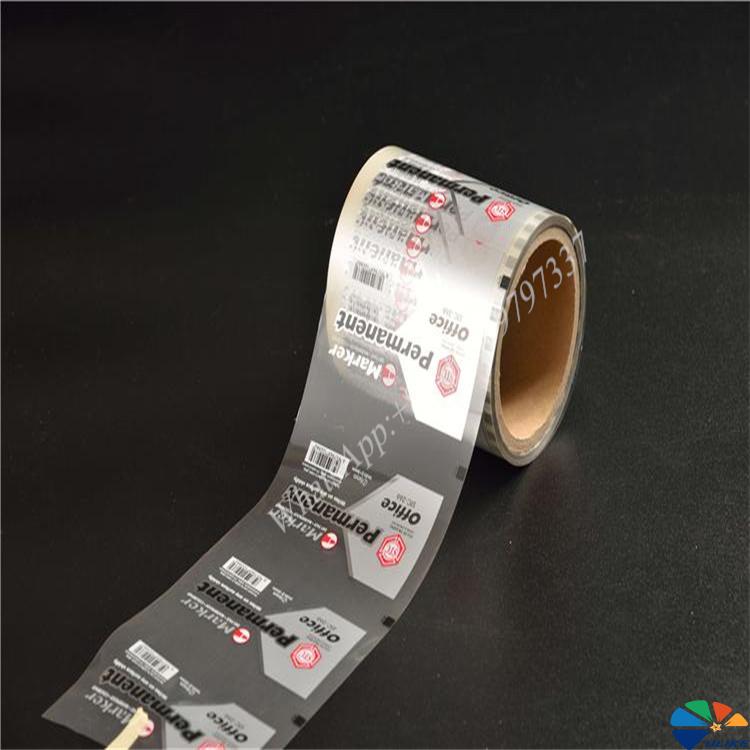

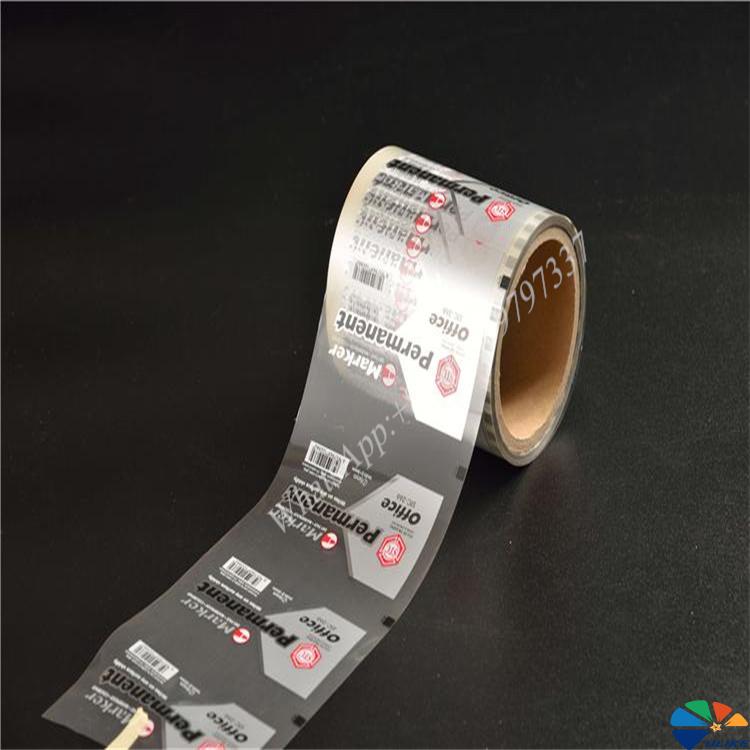

Heat transfer film with brushed metal effect is a high-performance decorative material that transfers brushed metal effect patterns to various product surfaces through heat transfer technology, giving them a unique visual texture and high-end appearance. This article will introduce in detail the working principle, main features, application areas and advantages of

brushed metal PET heat transfer film in modern manufacturing.

1. Working principle of brushed metal PET heat transfer film

The working principle of brushed metal PET heat transfer film (heat transfer film with brushed metal effect) is based on heat and pressure to transfer the pre-printed brushed metal effect pattern from the PET substrate to the product surface. The specific steps are as follows:

Design and printing: Design the pattern according to the needs, and use specific metal inks and processes to accurately print the brushed effect pattern on the PET transfer film.

Preheating stage: Before transfer, preheat the PET transfer film and the product surface to the appropriate temperature.

Transfer stage: Use hot pressing equipment to fit the transfer film tightly to the product surface, and transfer the pattern to the product surface by applying pressure and heat to form a brushed metal effect.

Cooling and shaping: After the transfer is completed, the product surface is cooled to ensure that the pattern and metal effect are firmly attached to the product surface.

2. Main features of metal brushed PET thermal transfer film

High adhesion: Metal brushed PET thermal transfer film can be firmly attached to the surface of various materials, such as plastic, metal, glass, etc., to ensure that the pattern does not fall off for a long time.

Brushed metal effect: The transferred pattern has a unique brushed metal texture, which enhances the grade and visual appeal of the product.

High definition: The transferred pattern has high resolution and rich details, which is suitable for complex patterns and fine designs.

Durability: The pattern is wear-resistant and scratch-resistant, has excellent weather resistance, and is suitable for use in various environments.

Environmental protection: It uses environmentally friendly materials and inks, meets environmental protection standards, is harmless to the human body, and does not pollute the environment.

3. Application fields

Electronic products: Used for surface decoration of electronic products such as mobile phone cases and laptops, providing a unique brushed metal texture and high-end appearance.

Fashion industry: Used for surface decoration of clothing, footwear and accessories to enhance the texture and market competitiveness of products.

Home decoration: used for surface decoration of home products such as furniture and wall decorations to increase the beauty and grade of interior decoration.

Packaging industry: used for high-end gift packaging, cosmetics packaging, etc., to increase the attractiveness and brand value of products.

4. Advantages of metal brushed PET thermal transfer film

High efficiency: It can quickly and efficiently transfer patterns on a large number of products, suitable for mass production.

High quality: The transferred pattern is full of color, clear in detail, and has excellent durability and weather resistance to ensure product quality.

Flexibility: The transfer parameters can be adjusted according to different design requirements to adapt to products of various sizes and shapes.

Environmental protection: The use of environmentally friendly inks and materials meets the requirements of modern society for green manufacturing and reduces environmental pollution.

Economic efficiency: The cost of thermal transfer technology is low, especially suitable for mass production, and has high economic benefits.

5. Precautions for use

Temperature and time control: According to the type of transfer film and the material of the product, adjust the appropriate temperature and time to ensure the best transfer effect.

Equipment maintenance: Regularly check and clean the hot pressing equipment to ensure the normal operation of the equipment and extend its service life.

Operational safety: During the operation, pay attention to protective measures to avoid high temperature burns and other safety hazards.

6. Equipment requirements

Hot pressing equipment: used to heat and apply pressure to make the transfer film closely bonded to the product surface to ensure the successful transfer of the pattern.

Control system: used to set and control parameters such as temperature, time and pressure to ensure the accuracy and stability of the transfer process.

Cooling device: used to quickly cool the product surface after the transfer is completed to ensure that the pattern is firmly attached.

7. Advantages of metal brushed PET thermal transfer film in modern manufacturing

Technological innovation: With the continuous innovation and progress of thermal transfer technology, metal brushed PET thermal transfer film has shown great potential in multiple manufacturing fields, meeting the market demand for high-quality decoration and brand logos.

Market competitiveness: Through metal brushed PET thermal transfer film technology, the appearance and brand image of the product can be greatly improved, and the competitiveness of the product in the market can be improved.

Environmental protection requirements: With the improvement of environmental awareness, the environmental protection characteristics of metal brushed PET thermal transfer film have been widely recognized and become an important part of green manufacturing.

Multifunctional application: Metal brushed PET heat transfer film is not only suitable for electronic products, fashion industry and home decoration, but also widely used in other fields, providing efficient and environmentally friendly decoration solutions for a variety of products.

8. Keywords and applications

Heat transfer film with brushed metal effect: brushed metal effect heat transfer film used for surface decoration of various products, providing efficient and high-definition pattern transfer effect.

Heat transfer sticker: heat transfer sticker suitable for small products, convenient and fast, suitable for personalized customization.

Heat transfer paper: heat transfer paper used for a variety of products, providing high-resolution pattern transfer effect.

Thermal transfer film: pattern transfer film used under high temperature conditions, ensuring stable transfer of patterns at high temperatures.

Conclusion

Metal brushed PET heat transfer film is an efficient, environmentally friendly decorative material with a unique brushed metal texture. It transfers exquisite patterns and metal effects to the surface of products through heat transfer technology (heat transfer film with brushed metal effect), and is widely used in electronic products, fashion industry, home decoration and packaging fields. Its high adhesion, high resolution and environmental protection characteristics make it an ideal choice for surface treatment in modern manufacturing. In the future, with the continuous advancement of technology and changes in market demand, metal brushed PET thermal transfer film will play a more important role in the manufacturing industry and promote the development and innovation of the industry.

![af]() Afrikaans

Afrikaans![sq]() Albanian

Albanian![am]() Amharic

Amharic![ar]() Arabic

Arabic![fr]() French

French![es]() Spanish

Spanish![ru]() Russian

Russian![de]() German

German![hy]() Armenian

Armenian![it]() Italian

Italian![ja]() Japanese

Japanese![ko]() Korean

Korean![pt]() Portuguese

Portuguese![hi]() Hindi

Hindi![az]() Azerbaijani

Azerbaijani![ro]() Romanian

Romanian![pl]() Polish

Polish![th]() Thai

Thai![el]() Greek

Greek![eu]() Basque

Basque![en]() English

English![zh-CN]() Chinese (Simplified)

Chinese (Simplified)![zh-TW]() Chinese (Traditional)

Chinese (Traditional)![be]() Belarusian

Belarusian![bn]() Bengali

Bengali![bs]() Bosnian

Bosnian![bg]() Bulgarian

Bulgarian![ca]() Catalan

Catalan![ceb]() Cebuano

Cebuano![ny]() Chichewa

Chichewa![co]() Corsican

Corsican![hr]() Croatian

Croatian![cs]() Czech

Czech![da]() Danish

Danish![nl]() Dutch

Dutch![eo]() Esperanto

Esperanto![et]() Estonian

Estonian![tl]() Filipino

Filipino![fi]() Finnish

Finnish![fy]() Frisian

Frisian![gl]() Galician

Galician![ka]() Georgian

Georgian![gu]() Gujarati

Gujarati![ht]() Haitian Creole

Haitian Creole![ha]() Hausa

Hausa![haw]() Hawaiian

Hawaiian![iw]() Hebrew

Hebrew![hmn]() Hmong

Hmong![hu]() Hungarian

Hungarian![is]() Icelandic

Icelandic![ig]() Igbo

Igbo![id]() Indonesian

Indonesian![ga]() Irish

Irish![jw]() Javanese

Javanese![kn]() Kannada

Kannada![kk]() Kazakh

Kazakh![km]() Khmer

Khmer![ku]() Kurdish (Kurmanji)

Kurdish (Kurmanji)![ky]() Kyrgyz

Kyrgyz![lo]() Lao

Lao![la]() Latin

Latin![lv]() Latvian

Latvian![lt]() Lithuanian

Lithuanian![lb]() Luxembourgish

Luxembourgish![mk]() Macedonian

Macedonian![mg]() Malagasy

Malagasy![ms]() Malay

Malay![ml]() Malayalam

Malayalam![mt]() Maltese

Maltese![mi]() Maori

Maori![mr]() Marathi

Marathi![mn]() Mongolian

Mongolian![my]() Myanmar (Burmese)

Myanmar (Burmese)![ne]() Nepali

Nepali![no]() Norwegian

Norwegian![ps]() Pashto

Pashto![fa]() Persian

Persian![pa]() Punjabi

Punjabi![sm]() Samoan

Samoan![gd]() Scottish Gaelic

Scottish Gaelic![sr]() Serbian

Serbian![st]() Sesotho

Sesotho![sn]() Shona

Shona![sd]() Sindhi

Sindhi![si]() Sinhala

Sinhala![sk]() Slovak

Slovak![sl]() Slovenian

Slovenian![so]() Somali

Somali![su]() Sudanese

Sudanese![sw]() Swahili

Swahili![sv]() Swedish

Swedish![tg]() Tajik

Tajik![ta]() Tamil

Tamil![te]() Telugu

Telugu![tr]() Turkish

Turkish![uk]() Ukrainian

Ukrainian![ur]() Urdu

Urdu![uz]() Uzbek

Uzbek![vi]() Vietnamese

Vietnamese![cy]() Welsh

Welsh![xh]() Xhosa

Xhosa![yi]() Yiddish

Yiddish![yo]() Yoruba

Yoruba![zu]() Zulu

Zulu