Introduction to

Three-Side Sealed Plastic Bags

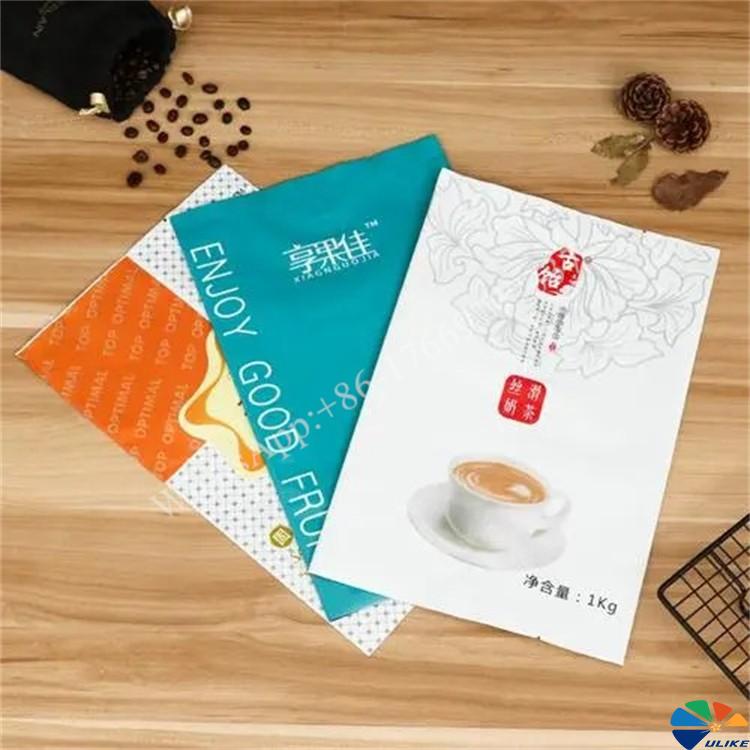

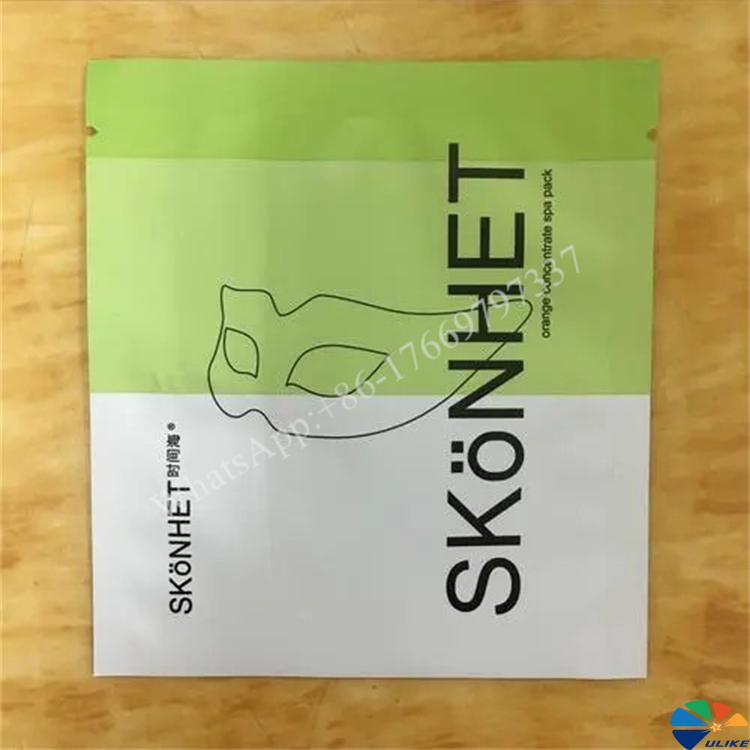

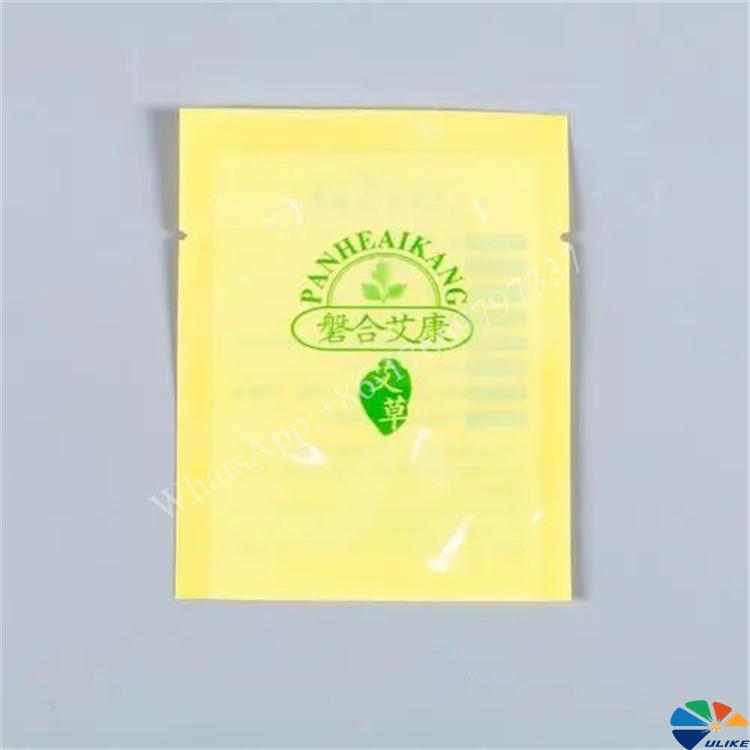

Three-Side Sealed Plastic Bags are plastic packaging bags made by three-side sealing process, which are widely used in food, medicine, cosmetics and industry. Its strong sealing, neat appearance, easy storage and transportation make it a popular packaging solution in the market.

1. Manufacturing process of

three-side sealed plastic bags

The manufacturing process of three-side sealed plastic bags mainly includes the following steps:

Material selection: Mainly use polyethylene (PE), polypropylene (PP), polyester (PET) and composite materials as raw materials.

Blowing process: The raw materials are melted and blown into film by a film blowing machine.

Printing process: According to customer needs, flexographic or gravure printing technology is used for printing on the film.

Laminating process: Two or more layers of film are compounded together by a laminating machine to enhance the physical properties of the bag.

Bag making process: The composite film is cut and sealed on three sides by a bag making machine to form a three-side sealed bag.

Cutting process: The three-side sealed bag is cut into the required size and necessary subsequent processing is performed, such as punching, adding zippers, etc.

2. Current usage status

Three-side sealed plastic bags are widely used around the world, and the main application areas include:

Food packaging: In the food industry, three-side sealed plastic bags are used to package various dry goods, snacks, frozen foods and condiments, etc., to ensure the freshness and hygiene of food.

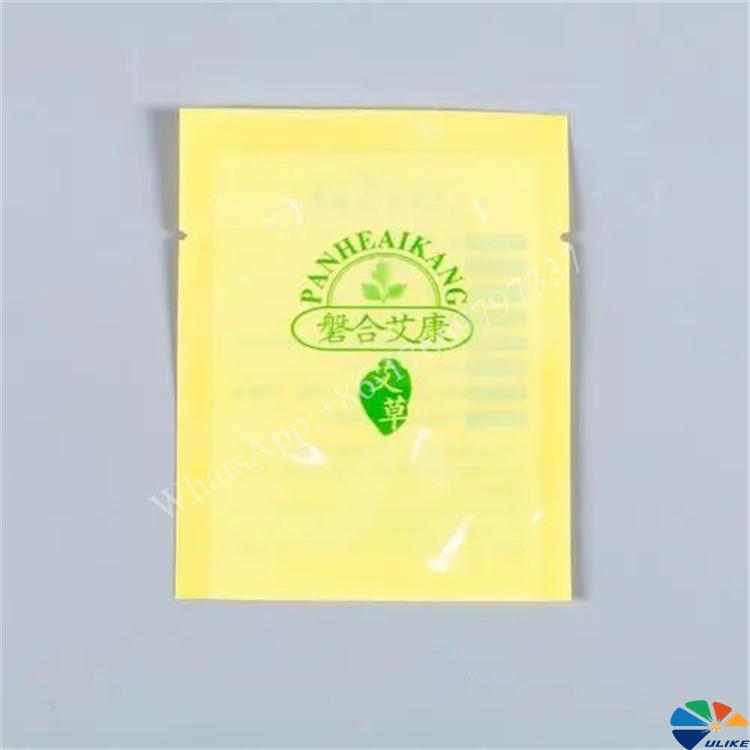

Medical packaging: Three-side sealed plastic bags are used in the pharmaceutical industry to package medicines, medical devices and disposable medical supplies, and have good moisture-proof and pollution-proof functions.

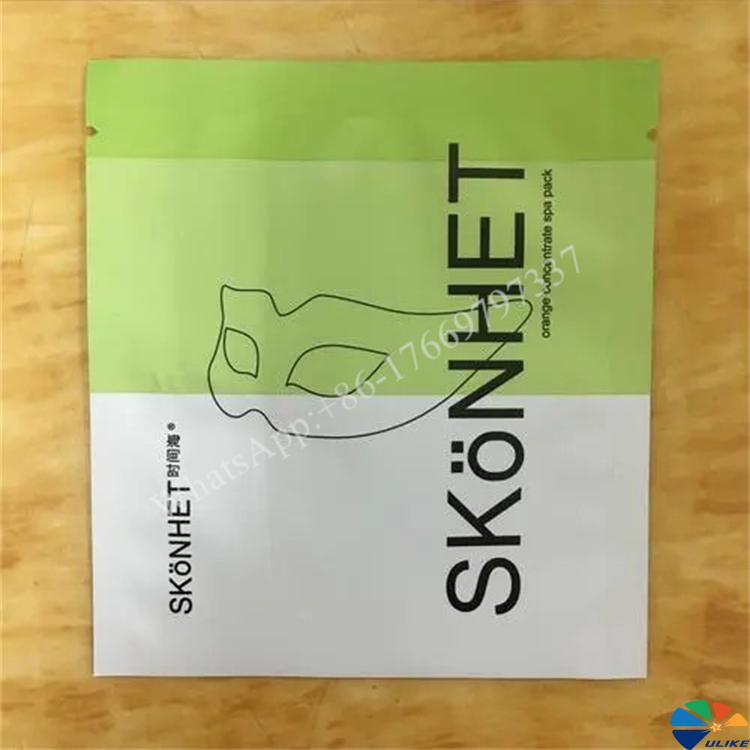

Cosmetic packaging: Three-side sealed plastic bags are widely used in the packaging of cosmetics, such as facial masks, shampoos, skin care products, etc., with high sealing and convenience.

Industrial packaging: In the industrial field, three-side sealed plastic bags are used to package parts, tools and other industrial products, which play a role in dust and moisture prevention.

Daily necessities packaging: Three-side sealed plastic bags are also widely used in daily necessities packaging, such as stationery, toys, electronic products, etc.

3. Future development trends

Application of environmentally friendly materials: With the improvement of environmental awareness, three-side sealed plastic bags will use more degradable and renewable materials, such as PLA (polylactic acid) and PHA (polyhydroxyalkanoate) to reduce environmental impact.

Smart packaging technology: In the future, smart packaging technology will be applied in three-side sealed plastic bags, such as embedding RFID chips to achieve product tracking and management and improve logistics efficiency.

Multifunctional design: Three-side sealed plastic bags will develop in a multifunctional direction, such as adding self-sealing strips, anti-counterfeiting labels and anti-theft devices to meet the needs of different customers.

Lightweight and high strength: Through the advancement of material science and manufacturing processes,

three-side sealed plastic bags will become lighter and thinner, while maintaining high strength and durability, reducing material use and costs.

Circular economy model: In the future, the recycling and reuse of three-side sealed plastic bags will become an industry trend, promoting the closed-loop circulation of plastic bags, reducing resource waste and environmental pollution.

Conclusion

Three-Side Sealed Plastic Bags are widely used in many industries for their excellent sealing, durability and production efficiency. With the advancement of technology and the improvement of environmental awareness, three-side sealed plastic bags will usher in new development opportunities in the application of environmentally friendly materials, smart packaging technology, multifunctional design, lightweight and high strength, and circular economy models. These trends not only improve product performance and user experience, but also promote the sustainable development of the industry.

Keywords

Three-Side Sealed Plastic Bags:

Three-Side Sealed Plastic Bags

Manufacturing process: The manufacturing steps include material selection, film blowing, printing, laminating, bag making and cutting processes.

Current use: Involving food packaging, pharmaceutical packaging, cosmetic packaging, industrial packaging and daily necessities packaging.

Future development trend: Involving environmentally friendly material application, intelligent packaging technology, multifunctional design, lightweight and high strength and circular economy model.

![af]() Afrikaans

Afrikaans![sq]() Albanian

Albanian![am]() Amharic

Amharic![ar]() Arabic

Arabic![fr]() French

French![es]() Spanish

Spanish![ru]() Russian

Russian![de]() German

German![hy]() Armenian

Armenian![it]() Italian

Italian![ja]() Japanese

Japanese![ko]() Korean

Korean![pt]() Portuguese

Portuguese![hi]() Hindi

Hindi![az]() Azerbaijani

Azerbaijani![ro]() Romanian

Romanian![pl]() Polish

Polish![th]() Thai

Thai![el]() Greek

Greek![eu]() Basque

Basque![en]() English

English![zh-CN]() Chinese (Simplified)

Chinese (Simplified)![zh-TW]() Chinese (Traditional)

Chinese (Traditional)![be]() Belarusian

Belarusian![bn]() Bengali

Bengali![bs]() Bosnian

Bosnian![bg]() Bulgarian

Bulgarian![ca]() Catalan

Catalan![ceb]() Cebuano

Cebuano![ny]() Chichewa

Chichewa![co]() Corsican

Corsican![hr]() Croatian

Croatian![cs]() Czech

Czech![da]() Danish

Danish![nl]() Dutch

Dutch![eo]() Esperanto

Esperanto![et]() Estonian

Estonian![tl]() Filipino

Filipino![fi]() Finnish

Finnish![fy]() Frisian

Frisian![gl]() Galician

Galician![ka]() Georgian

Georgian![gu]() Gujarati

Gujarati![ht]() Haitian Creole

Haitian Creole![ha]() Hausa

Hausa![haw]() Hawaiian

Hawaiian![iw]() Hebrew

Hebrew![hmn]() Hmong

Hmong![hu]() Hungarian

Hungarian![is]() Icelandic

Icelandic![ig]() Igbo

Igbo![id]() Indonesian

Indonesian![ga]() Irish

Irish![jw]() Javanese

Javanese![kn]() Kannada

Kannada![kk]() Kazakh

Kazakh![km]() Khmer

Khmer![ku]() Kurdish (Kurmanji)

Kurdish (Kurmanji)![ky]() Kyrgyz

Kyrgyz![lo]() Lao

Lao![la]() Latin

Latin![lv]() Latvian

Latvian![lt]() Lithuanian

Lithuanian![lb]() Luxembourgish

Luxembourgish![mk]() Macedonian

Macedonian![mg]() Malagasy

Malagasy![ms]() Malay

Malay![ml]() Malayalam

Malayalam![mt]() Maltese

Maltese![mi]() Maori

Maori![mr]() Marathi

Marathi![mn]() Mongolian

Mongolian![my]() Myanmar (Burmese)

Myanmar (Burmese)![ne]() Nepali

Nepali![no]() Norwegian

Norwegian![ps]() Pashto

Pashto![fa]() Persian

Persian![pa]() Punjabi

Punjabi![sm]() Samoan

Samoan![gd]() Scottish Gaelic

Scottish Gaelic![sr]() Serbian

Serbian![st]() Sesotho

Sesotho![sn]() Shona

Shona![sd]() Sindhi

Sindhi![si]() Sinhala

Sinhala![sk]() Slovak

Slovak![sl]() Slovenian

Slovenian![so]() Somali

Somali![su]() Sudanese

Sudanese![sw]() Swahili

Swahili![sv]() Swedish

Swedish![tg]() Tajik

Tajik![ta]() Tamil

Tamil![te]() Telugu

Telugu![tr]() Turkish

Turkish![uk]() Ukrainian

Ukrainian![ur]() Urdu

Urdu![uz]() Uzbek

Uzbek![vi]() Vietnamese

Vietnamese![cy]() Welsh

Welsh![xh]() Xhosa

Xhosa![yi]() Yiddish

Yiddish![yo]() Yoruba

Yoruba![zu]() Zulu

Zulu