Introduction

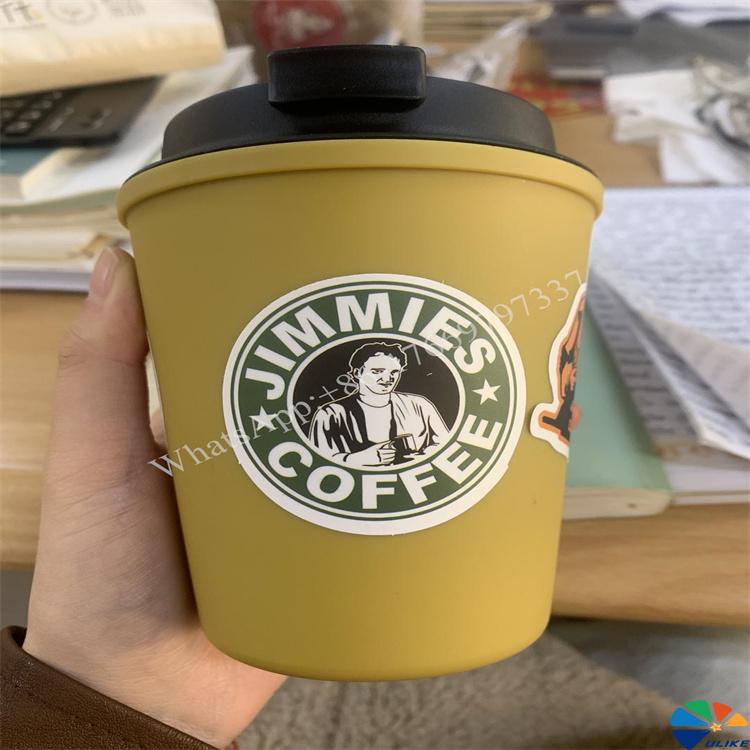

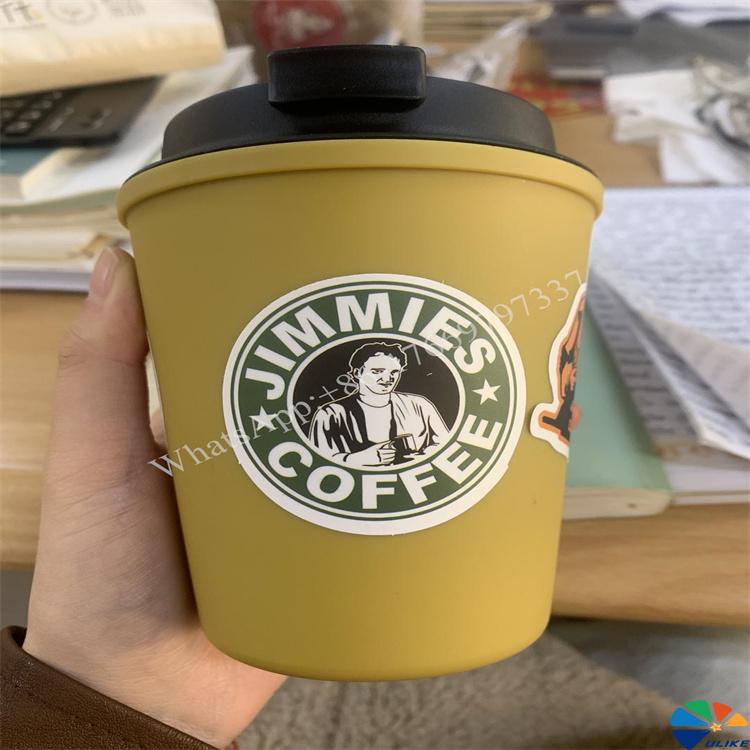

As a popular drink around the world, milk tea packaging is crucial to brand image and consumer experience.

In Mold Label For Milky Cups (IML) is an advanced packaging technology that integrates labels with plastic cups by embedding labels directly into plastic products during the injection molding process. This technology is widely used in milk tea packaging, which not only improves the appearance quality of the product, but also enhances its functionality and environmental protection characteristics. This article will introduce in detail the working principle, main features, application advantages and prospects of the in-mold label for milk tea cups in the modern packaging industry.

1. Working Principle

The in-mold label for milk tea cups technology places the pre-printed label inside the mold and then integrates the label with the plastic product during the injection molding process. The specific steps are as follows:

Design and printing: Design the label pattern according to the requirements and use high-quality inks and materials for printing.

Label placement: Place the printed label in a specific position of the mold to ensure that the label will not shift during the molding process.

Injection molding: Inject the plastic melt into the mold, and fuse the plastic and the label together through high temperature and high pressure to form an integrated milk tea cup.

Cooling and demoulding: After molding, the product in the mold is cooled and removed from the mold to form a plastic milk tea cup with a label.

2. Main features

High adhesion: The IML label is integrally molded with the plastic product, has extremely high adhesion, and is not easy to fall off.

Durability: The label pattern is wear-resistant and scratch-resistant, has excellent weather resistance and chemical stability, and is suitable for use in various environments.

Aesthetics: The label is perfectly integrated with the product surface, and no subsequent labeling operation is required, providing a high-quality appearance effect.

Anti-counterfeiting: Through complex printing processes and material selection, the anti-counterfeiting function can be increased and the anti-counterfeiting ability of the product can be improved.

Environmental protection: IML labels and plastic products can be recycled together, which meets environmental protection requirements.

3. Application advantages

Production efficiency: IML technology integrates labels and molding processes, simplifies the production process, and improves production efficiency.

Cost-effectiveness: Reduces the use of subsequent labeling operations and related equipment, and reduces production costs.

Consistency: The label is integrally formed with the product, avoiding problems such as label offset and bubbling that may occur in traditional labeling methods, ensuring product consistency and stability.

Flexibility: IML labels can be designed and printed according to different needs to adapt to diverse market needs.

Brand enhancement: High-quality label patterns and excellent appearance effects enhance the brand image and market competitiveness of the product.

4. Application areas

In-mold labeling technology for milk tea cups is widely used in various food packaging, especially in the following areas:

Milk tea packaging: used for the appearance decoration of various milk tea cups, providing excellent visual effects and product recognition.

Coffee cup packaging: suitable for coffee cups, ensuring the durability of packaging in normal and low temperature environments.

Pudding packaging: used for pudding cups, providing high-quality appearance and anti-counterfeiting functions.

Yogurt packaging: suitable for cup packaging of various yogurt products, providing excellent visual effects and brand display.

5. Precautions for use

Label design: When designing labels, the mold structure and molding process must be considered to ensure that the label does not shift during the molding process.

Material selection: Select appropriate label materials and inks to ensure the compatibility and adhesion of the label with the plastic melt.

Process control: strictly control the injection molding process parameters to ensure the perfect integration of labels and plastic products.

Equipment maintenance: regularly check and maintain molds and molding equipment to ensure the stability of the production process and product quality.

6. Equipment requirements

Mold design: molds used for

IML need to be designed with special label fixing devices to ensure the stability of labels during the molding process.

Injection molding equipment: high-performance injection molding equipment that can accurately control injection molding process parameters to ensure the integration of labels and plastic products.

Label supply system: automated label supply system to ensure accurate positioning and continuous supply of labels during the molding process.

7. Application prospects of in-mold stickers for milk tea cups in the modern packaging industry

Technological innovation: with the continuous innovation and progress of IML technology, in-mold stickers for milk tea cups have shown great potential in multiple food packaging fields, meeting the market's demand for high-quality packaging and brand logos.

Market competitiveness: through IML technology, the appearance and brand image of products can be greatly improved, and the competitiveness of products in the market can be improved.

Environmental protection requirements: with the improvement of environmental awareness, the environmental protection characteristics of IML technology have been widely recognized and have become an important part of green packaging.

Versatile application: IML technology is not only suitable for milk tea, pudding and yogurt packaging, but also widely used in other food and beverage packaging, providing efficient and environmentally friendly packaging solutions for a variety of products.

Conclusion

In Mold Label For Milky Cups is an efficient, environmentally friendly label technology with excellent decorative effect. Through the in-mold label technology, the label and plastic products are integrated into one, and it is widely used in milk tea packaging. Its high adhesion, high durability and excellent appearance make it an ideal choice in the modern food packaging industry. In the future, with the continuous advancement of technology and changes in market demand, the in-mold label technology for milk tea cups will play a more important role in the packaging industry and promote the development and innovation of the industry.

![af]() Afrikaans

Afrikaans![sq]() Albanian

Albanian![am]() Amharic

Amharic![ar]() Arabic

Arabic![fr]() French

French![es]() Spanish

Spanish![ru]() Russian

Russian![de]() German

German![hy]() Armenian

Armenian![it]() Italian

Italian![ja]() Japanese

Japanese![ko]() Korean

Korean![pt]() Portuguese

Portuguese![hi]() Hindi

Hindi![az]() Azerbaijani

Azerbaijani![ro]() Romanian

Romanian![pl]() Polish

Polish![th]() Thai

Thai![el]() Greek

Greek![eu]() Basque

Basque![en]() English

English![zh-CN]() Chinese (Simplified)

Chinese (Simplified)![zh-TW]() Chinese (Traditional)

Chinese (Traditional)![be]() Belarusian

Belarusian![bn]() Bengali

Bengali![bs]() Bosnian

Bosnian![bg]() Bulgarian

Bulgarian![ca]() Catalan

Catalan![ceb]() Cebuano

Cebuano![ny]() Chichewa

Chichewa![co]() Corsican

Corsican![hr]() Croatian

Croatian![cs]() Czech

Czech![da]() Danish

Danish![nl]() Dutch

Dutch![eo]() Esperanto

Esperanto![et]() Estonian

Estonian![tl]() Filipino

Filipino![fi]() Finnish

Finnish![fy]() Frisian

Frisian![gl]() Galician

Galician![ka]() Georgian

Georgian![gu]() Gujarati

Gujarati![ht]() Haitian Creole

Haitian Creole![ha]() Hausa

Hausa![haw]() Hawaiian

Hawaiian![iw]() Hebrew

Hebrew![hmn]() Hmong

Hmong![hu]() Hungarian

Hungarian![is]() Icelandic

Icelandic![ig]() Igbo

Igbo![id]() Indonesian

Indonesian![ga]() Irish

Irish![jw]() Javanese

Javanese![kn]() Kannada

Kannada![kk]() Kazakh

Kazakh![km]() Khmer

Khmer![ku]() Kurdish (Kurmanji)

Kurdish (Kurmanji)![ky]() Kyrgyz

Kyrgyz![lo]() Lao

Lao![la]() Latin

Latin![lv]() Latvian

Latvian![lt]() Lithuanian

Lithuanian![lb]() Luxembourgish

Luxembourgish![mk]() Macedonian

Macedonian![mg]() Malagasy

Malagasy![ms]() Malay

Malay![ml]() Malayalam

Malayalam![mt]() Maltese

Maltese![mi]() Maori

Maori![mr]() Marathi

Marathi![mn]() Mongolian

Mongolian![my]() Myanmar (Burmese)

Myanmar (Burmese)![ne]() Nepali

Nepali![no]() Norwegian

Norwegian![ps]() Pashto

Pashto![fa]() Persian

Persian![pa]() Punjabi

Punjabi![sm]() Samoan

Samoan![gd]() Scottish Gaelic

Scottish Gaelic![sr]() Serbian

Serbian![st]() Sesotho

Sesotho![sn]() Shona

Shona![sd]() Sindhi

Sindhi![si]() Sinhala

Sinhala![sk]() Slovak

Slovak![sl]() Slovenian

Slovenian![so]() Somali

Somali![su]() Sudanese

Sudanese![sw]() Swahili

Swahili![sv]() Swedish

Swedish![tg]() Tajik

Tajik![ta]() Tamil

Tamil![te]() Telugu

Telugu![tr]() Turkish

Turkish![uk]() Ukrainian

Ukrainian![ur]() Urdu

Urdu![uz]() Uzbek

Uzbek![vi]() Vietnamese

Vietnamese![cy]() Welsh

Welsh![xh]() Xhosa

Xhosa![yi]() Yiddish

Yiddish![yo]() Yoruba

Yoruba![zu]() Zulu

Zulu