The Dynamic World of Heat Transfer Film: Market Status, Trends, and Standards

The Dynamic World of

Heat Transfer Film: Market Status, Trends, and Standards

I. Introduction

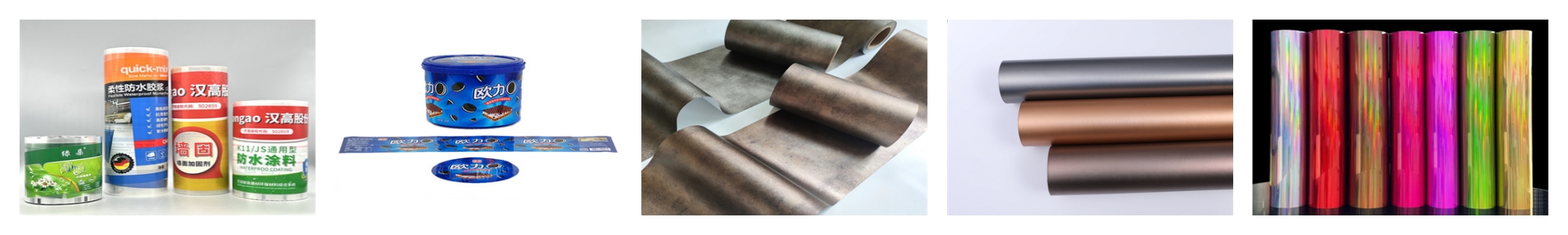

In an era defined by rapid technological advancements and an ever-increasing demand for customization, the heat transfer film industry has emerged as a pivotal player across a multitude of sectors. This versatile material, known for its ability to transfer intricate designs, vibrant colors, and durable finishes onto various substrates, has revolutionized product decoration, branding, and functional applications. From enhancing the aesthetic appeal of apparel to providing critical information on packaging, heat transfer films offer a cost-effective and efficient solution for adding value and distinction to products.

This article aims to provide a comprehensive analysis of the current market landscape for heat transfer films, delve into the burgeoning future trends that are set to redefine its trajectory, and outline the essential industry standards and regulations that govern its quality and safety. Our exploration will highlight the critical role of heat transfer film in driving innovation and meeting the evolving demands of consumers and industries worldwide, ensuring a professional yet accessible overview for both industry insiders and interested readers.

II. Current Market Landscape of Heat Transfer Film

The global heat transfer film market is a vibrant and expanding sector, characterized by continuous innovation and diverse applications. Its growth is intrinsically linked to the broader trends in manufacturing, consumer goods, and digital printing technologies.

Market Size and Growth

The global heat transfer film market has witnessed steady growth over the past decade, driven by increasing demand for product differentiation, brand recognition, and efficient decoration methods. Market reports indicate a consistent upward trajectory, with projections suggesting continued expansion in the coming years. This growth is fueled by both the mature markets in North America and Europe, where innovation and premium applications drive demand, and the rapidly expanding economies in Asia-Pacific, Latin America, and Africa, where industrialization and rising consumer spending create new opportunities.

Key Applications

The versatility of heat transfer film allows it to be utilized across a broad spectrum of industries:

•

Textile and Apparel: This remains one of the largest application segments. Heat transfer films are extensively used for decorating T-shirts, sportswear, fashion garments, workwear, and accessories. They offer advantages such as vibrant colors, intricate designs, durability, and the ability to personalize items quickly and efficiently.

•

Packaging: In the packaging industry, heat transfer films are employed for decorative purposes on various products, including food and beverage containers, cosmetics, and industrial goods. They provide high-quality graphics, metallic effects, and security features, enhancing product appeal and brand identity.

•

Automotive: The automotive sector utilizes heat transfer films for both interior and exterior applications. This includes decorative elements on dashboards, door panels, and trim, as well as functional applications like warning labels and branding that require high durability and resistance to environmental factors.

•

Electronics: From consumer electronics to industrial devices, heat transfer films are used for labels, decorative overlays, and functional markings. Their precision and ability to adhere to various surfaces make them ideal for complex electronic components.

•

Promotional Products and Signage: Customization is key in promotional items. Heat transfer films enable businesses to apply logos, slogans, and designs onto a wide range of products, including mugs, pens, bags, and signage, offering effective branding solutions.

Driving Factors

Several factors are propelling the demand for heat transfer film:

•

Increasing Demand for Customization and Personalization: Consumers and businesses alike are seeking unique and personalized products. Heat transfer technology allows for short-run production and bespoke designs, catering to this growing trend.

•

Growth of E-commerce and Fast Fashion: The rapid pace of e-commerce and the fast fashion industry demands quick turnaround times and flexible decoration options. Heat transfer films provide the speed and adaptability required to meet these dynamic market needs.

•

Advancements in Printing Technology: Continuous improvements in digital printing, screen printing, and gravure printing technologies have enhanced the quality, efficiency, and cost-effectiveness of heat transfer film production and application.

•

Demand for Durable and Aesthetically Pleasing Finishes: Industries require decorative and functional finishes that are not only visually appealing but also resistant to wear, washing, and environmental exposure. Modern heat transfer films offer superior durability and a wide range of aesthetic effects, including matte, gloss, metallic, and holographic finishes.

Challenges

Despite its robust growth, the heat transfer film market faces certain challenges:

•

Competition from Alternative Decoration Methods: Technologies such as direct-to-garment (DTG) printing, sublimation, embroidery, and direct printing on various substrates pose competition. Manufacturers must continuously innovate to maintain the competitive edge of heat transfer films.

•

Raw Material Price Fluctuations: The cost of raw materials, including polymers, adhesives, and inks, can be volatile, impacting production costs and profit margins.

•

Environmental Concerns and Sustainability Pressures: Growing global awareness of environmental issues is pushing the industry towards more sustainable practices. This includes developing eco-friendly films, reducing waste, and minimizing the use of hazardous substances, which can present R&D and production challenges.

In summary, the current market for heat transfer film is dynamic and expanding, driven by consumer trends and technological advancements. While challenges exist, the industry's adaptability and continuous innovation ensure its continued relevance and growth.

III. Future Trends and Growth Drivers in Heat Transfer Film

The heat transfer film market is poised for significant evolution, driven by a confluence of technological breakthroughs, shifting consumer preferences, and an increasing global emphasis on sustainability. These trends are not only expanding the market but also redefining the capabilities and applications of heat transfer technology.

Technological Advancements

Innovation remains at the forefront of the heat transfer film industry, with continuous developments enhancing product performance and application efficiency:

•

Development of New Film Materials: Research and development are focused on creating advanced film substrates that offer superior properties. This includes films with enhanced elasticity for stretchable fabrics, improved heat resistance for industrial applications, and specialized textures for unique aesthetic effects. The drive towards high-performance materials ensures that heat transfer films can meet the demands of increasingly sophisticated products.

•

Improved Adhesion and Durability: Manufacturers are constantly refining adhesive formulations to provide stronger bonds to a wider range of substrates, ensuring that designs remain intact through repeated washing, abrasion, and exposure to harsh environments. This focus on durability is crucial for applications in sportswear, outdoor gear, and automotive interiors.

•

Enhanced Printability and Color Vibrancy: Advances in ink technology and film coatings are leading to heat transfer films that can reproduce more vivid colors, sharper details, and complex gradients. This allows for greater creative freedom and higher-quality decorative outcomes, meeting the demands of high-end fashion and branding.

•

Integration with Digital Printing Technologies: The synergy between heat transfer films and digital printing (such as inkjet and laser printing) is a major trend. This integration enables on-demand production, mass customization, and shorter lead times, making heat transfer technology more agile and responsive to market needs. Digital heat transfers reduce setup costs and allow for variable data printing, opening up new possibilities for personalized products.

New Application Areas

The versatility of heat transfer film is leading to its adoption in novel and emerging sectors:

•

Smart Textiles and Wearables: As smart textiles gain traction, heat transfer films are being developed to integrate functional elements like sensors, conductive pathways, and interactive displays onto fabrics. This allows for the creation of wearable technology that is both functional and comfortable, without compromising the textile's properties.

•

Medical Devices: In the medical field, heat transfer films are finding applications in labeling, branding, and even functional components for devices that require sterile, durable, and precise markings.

•

Advanced Industrial Applications: Beyond traditional decorative uses, heat transfer films are being explored for industrial purposes such as anti-counterfeiting measures, functional coatings, and specialized markings on components that require high resistance to chemicals, heat, or abrasion.

Sustainability Focus

Environmental consciousness is a growing imperative across all industries, and the heat transfer film market is no exception. Sustainability initiatives are driving innovation in several key areas:

•

Biodegradable and Recyclable Heat Transfer Films: Manufacturers are investing in the development of films made from bio-based polymers or materials that can be easily recycled, reducing the environmental footprint of products at the end of their life cycle.

•

Reduced VOC Emissions in Production: Efforts are being made to minimize Volatile Organic Compound (VOC) emissions during the manufacturing process of heat transfer films and their application, contributing to cleaner production and safer working environments.

•

Energy-Efficient Application Processes: The development of low-temperature heat transfer films and more efficient heat presses aims to reduce energy consumption during the application phase, aligning with broader energy conservation goals.

Market Expansion

Geographical and sectoral expansion will continue to fuel growth:

•

Growth in Emerging Economies: As disposable incomes rise and manufacturing capabilities expand in developing countries, the demand for decorated and branded products will surge, creating significant opportunities for heat transfer film manufacturers.

•

Increased Adoption in Niche Markets: Specialized applications in areas like automotive interiors, consumer electronics, and high-performance industrial goods will see increased adoption as the benefits of heat transfer technology become more widely recognized and tailored solutions become available.

These trends collectively paint a picture of a dynamic and innovative market for heat transfer film, one that is continuously adapting to technological advancements, expanding into new territories, and embracing sustainable practices to meet the evolving demands of a globalized economy.

IV. Industry Standards and Regulations for Heat Transfer Film

To ensure product quality, safety, and environmental responsibility, the heat transfer film industry adheres to a range of international and national standards and regulations. These guidelines are crucial for manufacturers, suppliers, and end-users, providing benchmarks for performance, material composition, and application safety.

Quality Standards

Quality is paramount in the heat transfer film market, as the performance of the film directly impacts the final product. Key quality parameters often addressed by industry standards include:

•

Adhesion Strength: This measures how well the heat transfer film adheres to the substrate after application. Standards typically specify minimum adhesion values to ensure the design does not peel or crack prematurely.

•

Washability/Durability: Especially critical for textile applications, these standards (e.g., ISO 6330, AATCC 135 for textiles) assess the film's ability to withstand repeated washing, drying, and ironing cycles without degradation, fading, or detachment. This ensures the longevity of the decorated item.

•

Color Fastness: Standards evaluate the resistance of the film's colors to fading when exposed to light, washing, or rubbing. This is vital for maintaining the aesthetic integrity of the design over time.

•

Scratch and Abrasion Resistance: For applications in automotive interiors, electronics, or promotional products, the film's resistance to physical damage is crucial. Standards define testing methods to quantify this resistance, ensuring the film can withstand daily wear and tear.

Safety and Environmental Regulations

With increasing consumer awareness and regulatory scrutiny, the safety and environmental impact of heat transfer films are becoming ever more important. Regulations often focus on the chemical composition of the films and their manufacturing processes:

•

REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) Compliance: These European regulations restrict the use of certain hazardous substances in products. Manufacturers of heat transfer films must ensure their products comply with these directives, particularly for films exported to or used within the EU.

•

CPSIA (Consumer Product Safety Improvement Act): For heat transfer films used on children's products in the United States, compliance with CPSIA is mandatory. This includes restrictions on lead content and phthalates, ensuring the safety of young consumers.

•

OEKO-TEX Standard 100: This is a globally recognized independent testing and certification system for textile products. Heat transfer films used on textiles often seek OEKO-TEX certification to assure consumers that the product is free from harmful substances and safe for human ecological terms.

•

Regulations on VOCs (Volatile Organic Compounds) and Hazardous Substances: Various national and regional regulations aim to limit the emission of VOCs during the manufacturing and application of heat transfer films, as well as restrict the use of other hazardous chemicals, promoting cleaner production and healthier environments.

Testing and Certification

To demonstrate compliance with these myriad standards and regulations, third-party testing and certification play a vital role. Independent laboratories conduct rigorous tests to verify product claims and ensure adherence to specified benchmarks. Certifications not only build consumer trust but also facilitate market access, especially in regions with strict regulatory frameworks. Manufacturers often highlight their certifications (e.g., ISO 9001 for quality management, ISO 14001 for environmental management) as a testament to their commitment to quality and responsible production.

Adherence to these comprehensive industry standards and regulations is not merely a legal obligation but a strategic imperative for companies in the heat transfer film market. It ensures product reliability, protects consumer health, minimizes environmental impact, and ultimately fosters a sustainable and competitive industry.

V. Conclusion

The heat transfer film market is a testament to innovation and adaptability, continuously evolving to meet the dynamic demands of various industries. From its foundational role in textile decoration to its expanding presence in packaging, automotive, and electronics, heat transfer technology offers unparalleled versatility and aesthetic appeal.

As we look to the future, the market is set for sustained growth, driven by technological advancements that promise enhanced performance, greater sustainability, and broader application possibilities. The integration of digital printing, the development of eco-friendly materials, and the exploration of new functional applications in smart textiles and medical devices will undoubtedly redefine the landscape of this industry.

Crucially, the adherence to stringent industry standards and regulations will remain a cornerstone of the heat transfer film market. These guidelines ensure not only the quality and durability of products but also the safety of consumers and the protection of the environment. For manufacturers and innovators in this space, a commitment to these principles, coupled with a forward-thinking approach to technology and sustainability, will be key to unlocking the full potential of heat transfer film and securing a leading position in this exciting and ever-changing market.

![af]() Afrikaans

Afrikaans![sq]() Albanian

Albanian![am]() Amharic

Amharic![ar]() Arabic

Arabic![fr]() French

French![es]() Spanish

Spanish![ru]() Russian

Russian![de]() German

German![hy]() Armenian

Armenian![it]() Italian

Italian![ja]() Japanese

Japanese![ko]() Korean

Korean![pt]() Portuguese

Portuguese![hi]() Hindi

Hindi![az]() Azerbaijani

Azerbaijani![ro]() Romanian

Romanian![pl]() Polish

Polish![th]() Thai

Thai![el]() Greek

Greek![eu]() Basque

Basque![en]() English

English![zh-CN]() Chinese (Simplified)

Chinese (Simplified)![zh-TW]() Chinese (Traditional)

Chinese (Traditional)![be]() Belarusian

Belarusian![bn]() Bengali

Bengali![bs]() Bosnian

Bosnian![bg]() Bulgarian

Bulgarian![ca]() Catalan

Catalan![ceb]() Cebuano

Cebuano![ny]() Chichewa

Chichewa![co]() Corsican

Corsican![hr]() Croatian

Croatian![cs]() Czech

Czech![da]() Danish

Danish![nl]() Dutch

Dutch![eo]() Esperanto

Esperanto![et]() Estonian

Estonian![tl]() Filipino

Filipino![fi]() Finnish

Finnish![fy]() Frisian

Frisian![gl]() Galician

Galician![ka]() Georgian

Georgian![gu]() Gujarati

Gujarati![ht]() Haitian Creole

Haitian Creole![ha]() Hausa

Hausa![haw]() Hawaiian

Hawaiian![iw]() Hebrew

Hebrew![hmn]() Hmong

Hmong![hu]() Hungarian

Hungarian![is]() Icelandic

Icelandic![ig]() Igbo

Igbo![id]() Indonesian

Indonesian![ga]() Irish

Irish![jw]() Javanese

Javanese![kn]() Kannada

Kannada![kk]() Kazakh

Kazakh![km]() Khmer

Khmer![ku]() Kurdish (Kurmanji)

Kurdish (Kurmanji)![ky]() Kyrgyz

Kyrgyz![lo]() Lao

Lao![la]() Latin

Latin![lv]() Latvian

Latvian![lt]() Lithuanian

Lithuanian![lb]() Luxembourgish

Luxembourgish![mk]() Macedonian

Macedonian![mg]() Malagasy

Malagasy![ms]() Malay

Malay![ml]() Malayalam

Malayalam![mt]() Maltese

Maltese![mi]() Maori

Maori![mr]() Marathi

Marathi![mn]() Mongolian

Mongolian![my]() Myanmar (Burmese)

Myanmar (Burmese)![ne]() Nepali

Nepali![no]() Norwegian

Norwegian![ps]() Pashto

Pashto![fa]() Persian

Persian![pa]() Punjabi

Punjabi![sm]() Samoan

Samoan![gd]() Scottish Gaelic

Scottish Gaelic![sr]() Serbian

Serbian![st]() Sesotho

Sesotho![sn]() Shona

Shona![sd]() Sindhi

Sindhi![si]() Sinhala

Sinhala![sk]() Slovak

Slovak![sl]() Slovenian

Slovenian![so]() Somali

Somali![su]() Sudanese

Sudanese![sw]() Swahili

Swahili![sv]() Swedish

Swedish![tg]() Tajik

Tajik![ta]() Tamil

Tamil![te]() Telugu

Telugu![tr]() Turkish

Turkish![uk]() Ukrainian

Ukrainian![ur]() Urdu

Urdu![uz]() Uzbek

Uzbek![vi]() Vietnamese

Vietnamese![cy]() Welsh

Welsh![xh]() Xhosa

Xhosa![yi]() Yiddish

Yiddish![yo]() Yoruba

Yoruba![zu]() Zulu

Zulu