The Fixture for Hollow Products is a fixture designed for hollow structural products to ensure that these products remain stable and precisely positioned during the heat transfer process. The fixture is widely used in the fields of electronic products, household goods, beverage bottles, cosmetic containers, etc.

Functions and Features

High adaptability: Designed specifically for hollow products, suitable for hollow objects of various shapes and sizes.

High-precision positioning: Ensure that the hollow product maintains precise position and stability during the transfer process, ensuring perfect alignment of the pattern.

Efficient production: Simplify the clamping process, shorten production preparation time, and improve overall production efficiency.

Modular design: It can be adjusted and combined according to the needs of different products, increasing the versatility and flexibility of the fixture.

Durable material: Made of high-strength wear-resistant materials to ensure reliability and stability for long-term use.

Application field

The Fixture for Hollow Products is widely used in the following fields:

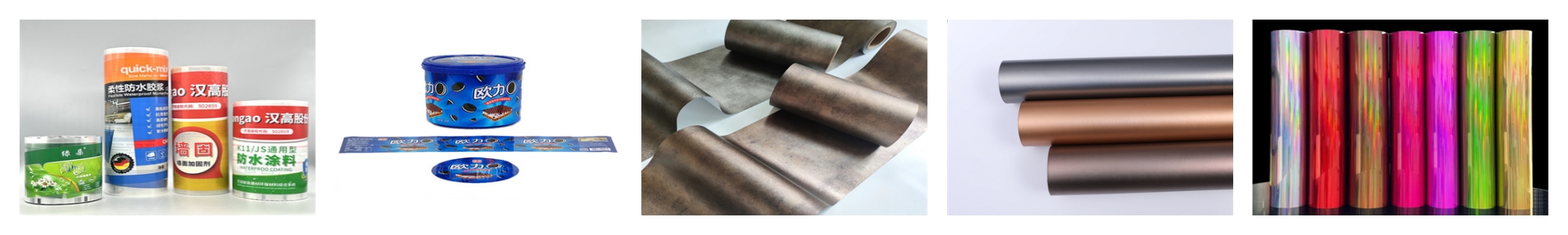

Electronic products: such as heat transfer of hollow electronic products such as earphone shells and remote control shells.

Household items: such as surface decoration of various hollow home decorations, containers, etc.

Beverage bottles: Pattern transfer of beverage containers such as plastic bottles and glass bottles.

Cosmetic containers: Surface decoration of hollow packaging containers such as cosmetic bottles and cans.

Industrial containers: Logos and decorations of hollow barrels and cans for industrial use.

Advantages

Improve transfer quality: Ensure the clarity and consistency of the pattern and improve the appearance quality of the product.

Reduce production losses: Reduce the frequency of movement and adjustment of products during the production process and reduce the scrap rate.

Improve production efficiency: Quickly fix and position hollow products and significantly improve production efficiency.

Enhance market competitiveness: Improve the market appeal and competitiveness of products through high-quality transfer effects.

Future development trends

With the continuous changes in market demand and the advancement of technology, the development trend of hollow product fixtures for thermal transfer machines (Fixture For Hollow Products) is mainly

concentrated in the following aspects:

Intelligent development: Integrate intelligent sensors and control systems to achieve automated and intelligent production.

High-precision manufacturing: Use advanced manufacturing technology and materials to further improve the precision and durability of fixtures.

Multifunctional integration: Develop universal fixtures suitable for more types of hollow products to enhance their adaptability and flexibility.

Lightweight design: Use new lightweight materials to reduce the weight of fixtures and improve ease of operation.

Customized service: Provide personalized fixture design and manufacturing solutions according to customer needs.

Conclusion

Fixture For Hollow Products plays a key role in the thermal transfer process. It not only improves production efficiency and product quality, but also significantly reduces production costs and scrap rates. With the development trend of intelligence, high precision, multi-function, lightweight and customization, fixtures for hollow products will usher in a broader market prospect and application space.

Blow molding product fixtures are used on

heat transfer machines to position and support products during heat transfer so

that the products can withstand sufficient hot stamping pressure and achieve

precise hot stamping effects.

![af]() Afrikaans

Afrikaans![sq]() Albanian

Albanian![am]() Amharic

Amharic![ar]() Arabic

Arabic![fr]() French

French![es]() Spanish

Spanish![ru]() Russian

Russian![de]() German

German![hy]() Armenian

Armenian![it]() Italian

Italian![ja]() Japanese

Japanese![ko]() Korean

Korean![pt]() Portuguese

Portuguese![hi]() Hindi

Hindi![az]() Azerbaijani

Azerbaijani![ro]() Romanian

Romanian![pl]() Polish

Polish![th]() Thai

Thai![el]() Greek

Greek![eu]() Basque

Basque![en]() English

English![zh-CN]() Chinese (Simplified)

Chinese (Simplified)![zh-TW]() Chinese (Traditional)

Chinese (Traditional)![be]() Belarusian

Belarusian![bn]() Bengali

Bengali![bs]() Bosnian

Bosnian![bg]() Bulgarian

Bulgarian![ca]() Catalan

Catalan![ceb]() Cebuano

Cebuano![ny]() Chichewa

Chichewa![co]() Corsican

Corsican![hr]() Croatian

Croatian![cs]() Czech

Czech![da]() Danish

Danish![nl]() Dutch

Dutch![eo]() Esperanto

Esperanto![et]() Estonian

Estonian![tl]() Filipino

Filipino![fi]() Finnish

Finnish![fy]() Frisian

Frisian![gl]() Galician

Galician![ka]() Georgian

Georgian![gu]() Gujarati

Gujarati![ht]() Haitian Creole

Haitian Creole![ha]() Hausa

Hausa![haw]() Hawaiian

Hawaiian![iw]() Hebrew

Hebrew![hmn]() Hmong

Hmong![hu]() Hungarian

Hungarian![is]() Icelandic

Icelandic![ig]() Igbo

Igbo![id]() Indonesian

Indonesian![ga]() Irish

Irish![jw]() Javanese

Javanese![kn]() Kannada

Kannada![kk]() Kazakh

Kazakh![km]() Khmer

Khmer![ku]() Kurdish (Kurmanji)

Kurdish (Kurmanji)![ky]() Kyrgyz

Kyrgyz![lo]() Lao

Lao![la]() Latin

Latin![lv]() Latvian

Latvian![lt]() Lithuanian

Lithuanian![lb]() Luxembourgish

Luxembourgish![mk]() Macedonian

Macedonian![mg]() Malagasy

Malagasy![ms]() Malay

Malay![ml]() Malayalam

Malayalam![mt]() Maltese

Maltese![mi]() Maori

Maori![mr]() Marathi

Marathi![mn]() Mongolian

Mongolian![my]() Myanmar (Burmese)

Myanmar (Burmese)![ne]() Nepali

Nepali![no]() Norwegian

Norwegian![ps]() Pashto

Pashto![fa]() Persian

Persian![pa]() Punjabi

Punjabi![sm]() Samoan

Samoan![gd]() Scottish Gaelic

Scottish Gaelic![sr]() Serbian

Serbian![st]() Sesotho

Sesotho![sn]() Shona

Shona![sd]() Sindhi

Sindhi![si]() Sinhala

Sinhala![sk]() Slovak

Slovak![sl]() Slovenian

Slovenian![so]() Somali

Somali![su]() Sudanese

Sudanese![sw]() Swahili

Swahili![sv]() Swedish

Swedish![tg]() Tajik

Tajik![ta]() Tamil

Tamil![te]() Telugu

Telugu![tr]() Turkish

Turkish![uk]() Ukrainian

Ukrainian![ur]() Urdu

Urdu![uz]() Uzbek

Uzbek![vi]() Vietnamese

Vietnamese![cy]() Welsh

Welsh![xh]() Xhosa

Xhosa![yi]() Yiddish

Yiddish![yo]() Yoruba

Yoruba![zu]() Zulu

Zulu